Our bespoke EPDM roofing membranes are the perfect solution for your shaped roof. Each roof membrane is prefabricated in our factory to your requirements.

Benefits of a bespoke roof membrane

There are several benefits to getting your roof membrane bespoke made, including:

- No onsite joining – our bespoke membranes come as a single piece, so there is no need to undertake joins onsite.

- Quicker install – lay out your roof, fix it down, detail the perimeters and you’re done. When site schedules or (more likely!) the weather leaves you a tight window for installing your roof, not having to join sections of EPDM makes the job quicker and more efficient to complete.

- Less waste and few materials on site – having a single, prefabricated membrane means you will not have to cut the corner out of a larger piece of liner or have tape and primer on-site for joining multiple membranes because all that work has been done for you.

- Tested seams in our factory – all our joins are completed and tested in our factory under ISO 9001:2015 quality conditions so you can be confident that the finished membrane will be of the highest quality.

How do we do it?

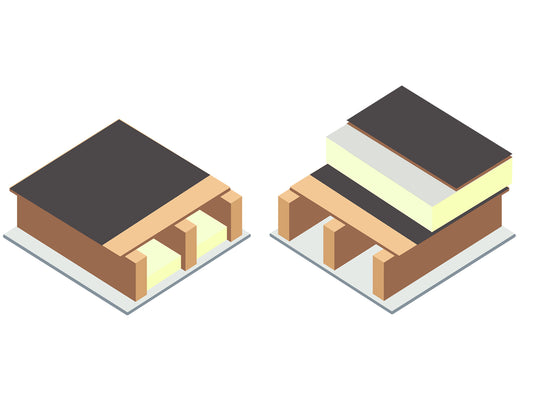

Unlike other EPDM roofing membranes on the market, RubberTop can be joined via both a tape system and by vulcanising or hot-bonding. Hot-bonding involves creating a sandwich of two layers of the membrane with tape in between. A hot-bonding press is then used to apply pressure and heat which causes a chemical bond between the layers in the membrane sandwich. A vulcanised bond is very strong as a result of this.

At Flexible Roofing Supplies, we have been hot-bonding rubber membranes for over 40 years, so we have a lot of experience with the process.

What shapes can we make?

Bespoke EPDM membranes can be made in many shapes, but the most popular are L and T shapes.

Contact us to find out more about our bespoke EPDM membranes.